Need Help?

Technical Guarantee Section

Our production line is designed around quality standards, special attention being paid to safety and functionality. Being in close contact with our customers enables us to detect many improvements and new products and needs that help us to constantly improve.

Firstly, we study the market, analysing social needs and demands and observing existing products. Then, we consider the alternatives, as regards possible development options, from which we choose the most appropriate. To develop the idea, the suppliers involved and the schedule are considered.

The next step is the preliminary product design, outlining diagrams and plans, defining the preliminary characteristics and estimating costs. Next, we conduct a feasibility study and design the prototype. After that, the calculations and assembly are carried out, using the plans of the prototype and detailed drawings and the materials and finishes are selected. After these stages of the manufacturing process, the first product is tested to verify validation. If everything is correct, the prototype is requested, the technical and assembly documents are compiled, the prototype is tested and it is tested and assembled, any possible operation and assembly problems being noted.

A validation test is carried out again and, if all the conclusions are optimal, the product is standardised based on technical and commercial procedures. In the final phase of the process, the detailed drawings are prepared, the products are coded and the manuals are designed. The descriptions are then written up, the images are designed and the product videos are edited. Finally, the prices are set and it goes on sale.

The mezzanine systems manufactured by TECRO have legal backing on all levels of protection. In 2007 we acquired the Spanish patent TecroOne for our industrial structures. One year later, the TecroStar brand was born. The brands TECRO, TecroOne and TecroStar are currently entities registered in Europe.

In addition, TECRO Montadores holds both the Spanish and international patents for manufacturing telescopic mezzanines. Similarly, like most companies who operate within the law, we have a series of duties and rights that if breached could lead to significant infractions and legal penalties.

Any user or customer can read our Privacy Policy, published on the website www.tecrostar.com/, which sets out the limits to using the information and images that appear in the aforementioned section. TECRO is also supported by a Team of Legal Advisors to guarantee the reliability and quality of our products.

TECRO's experience in all types of sectors guarantees a good result. Our story begins in 1999 as assemblers, assembling the products of storage system manufacturers. Over the last two decades we have created more than 350,000 m2 of surface area, making use of the height of our customers’ spaces.

Over the years we have developed projects for brands like Amazon, Primark, Seat-Volkswagen, BMW, Airbus, Kawasaki, Tuc Tuc, AR Sistemas, Harley Davidson, KTM Bizkaia, Ulma, Gas Monkey, Ead Casa, and others.

We are the only Spanish company dedicated to researching, designing and assembling portable high spaces for all kinds of purposes. We currently have distributors in Spain, France, Italy, Singapore and Hong Kong.

In the final design phase the prototype is assembled in the test area; possible improvements to aid assembly or optimise the product specifications are studied.

When the prototype has been validated, it is standardised and published.

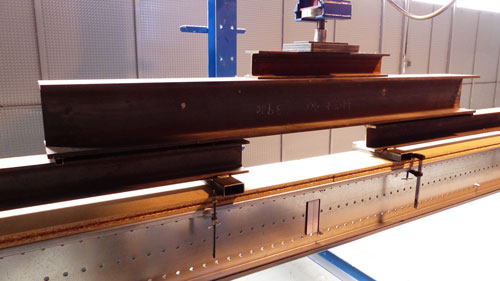

TECRO carries out exhaustive studies of the mechanical behaviour of our portable mezzanines to produce robust and stable structures In our facilities we have a material strength testing area, with a press of up to 15 tons, which allows us to perform exhaustive studies of the real behaviour of many components; beams, boards, steps, joints, etc., which are used to validate the theoretical results of the calculation programmes.

The flexure tests check bending and the ultimate strength of the components.

TECRO products come with a 10-year guarantee. Our technical solutions comply with the most demanding European building regulations. In fact, we have sat on the Spanish Governing Board of the FEM (Federation of European Materials Handling).

The calculations are based on the Eurocodes, current European regulations. Other standards are also taken into account, such as the Spanish Technical Building Code (CTE), the Structural Steel Code (EAE), ISO 14122, etc.

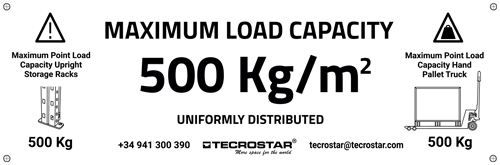

Pursuant to this legislation, various safety coefficients are used:

- Coefficients of Load Increments (1.5 for live loads and 1.35 for the weight of the structure itself)

- Partial strength coefficients for each type of material (1.01 for steel used for columns, beams, connectors, etc.; 1.25 for components used for joints and hardware; and 3.25 for the P4 chipboard panels for the flooring).

Various programs are used that aid 3D mechanical design and structural calculation with endless components.

Tecrostar products are manufactured with the most suitable materials for the proposed technical solutions, combining wood, steel and top quality aluminium.

- The steels used for beams, columns and other components are fit for structural uses with a high yield strength (S235, S275 or S3555, as required). The pieces are manufactured using maximum precision laser cutting, folding and pressing processes. Next a powder coating is applied and they are baked in the oven, offering maximum adhesion and an outstanding finish.

- Structure hardware grade 8.8

- Anodized aluminium apt for outdoor use

- The wood panels used for the mezzanine flooring can be made of European radiata pine plywood or high density structural chipboard. All the boards are tongue and groove on all four sides to prevent faults and unevenness at the joints of the modules.

- Other wooden components, such as the steps and parts of the handrails, are made from top quality beech.

TECRO has earned certification from the AEM, the federation of Spanish materials handling. We have also received a Gold Medal Award of Merit from the INPEX (Invention and New Product Exposition), the top award for innovation at the largest Invention Exposition in the USA.